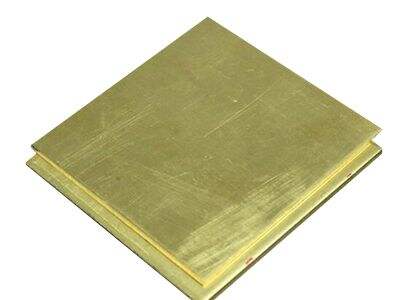

Brass is a distinct metal formed from a combination of copper and zinc. There are plenty of parts or things which brass is used to make such as decorations, jewelry, musical instruments etc. Cold-rolled brass sheets require a series of carefully controlled processes to ensure the final product is strong and durable.

What is Brass?

And this brings us to brass, which is an alloy of copper and zinc. Zinc is added in increasing quantities reinforcing the brass. More copper makes for softer brass metal plate that can bend more easily. Xinye metal provides high-quality brass sheet with a special formula which can be used for many applications.

How is Brass Made?

To make brass sheets, copper and zinc are melted together in a furnace. They are melted and poured and made into large molds. These blocks are pressed into thin sheets according to rolling mill. They cut the sheets into different sizes and shapes based on customer preferences.

Quality Checking of Brass Sheets

In order to ensure the quality of the brass sheets, Xinye metal has very strict checks in the process of making brass sheets. Brass sheets are carefully inspected for defects in each batch. Any sheets that fail to meet the standard are returned for recycling. This ensures that only quality brass sheet are shipped to customers.

Scholastic-Essays using technology in brass making

Mika: "Technology makes brass sheets better. Computer-controlled machines ensure that the sheets are the correct thickness and size. Doing so will help maintain the consistency in quality. They are using the advanced technology to enhance the brass sheet metal manufacturing process and deliver the best.

Brass Sheet Industry: New concepts

Brass sheet industry is an evolving industry with innovations. A trend is eco-friendly brass sheet manufacturing कंपन कपण. Xinye Metal makes fewer energy and waste that are good for the environment. They recycle scrap metal and run on renewable energy to aid in saving the Earth.